Picking the wrong countertop material can cost you thousands in repairs within a few years. Heat damage, deep scratches, and stains add up fast when your surface can’t handle daily use.

Two reliable countertop options solve these problems. Popular choices for homeowners are ultra-compact surfaces and solid surfaces.

Ultra-compact brands like Dekton handle high heat and heavy daily use. Solid surface options like Corian offer a seamless look and a lower upfront cost.

This guide compares solid surface countertops vs ultra-compact countertops. You will learn which material fits your lifestyle, space, and design needs.

TL;DR

- Ultra-compact surfaces resist extreme temperatures and last 25+ years

- Solid surface materials are easy to repair and last 10-20 years

- Choose ultra-compact countertops for outdoor or heavy-use areas

- Choose solid surface countertops for curved shapes and a seamless look

What Is an Ultra Compact Countertop?

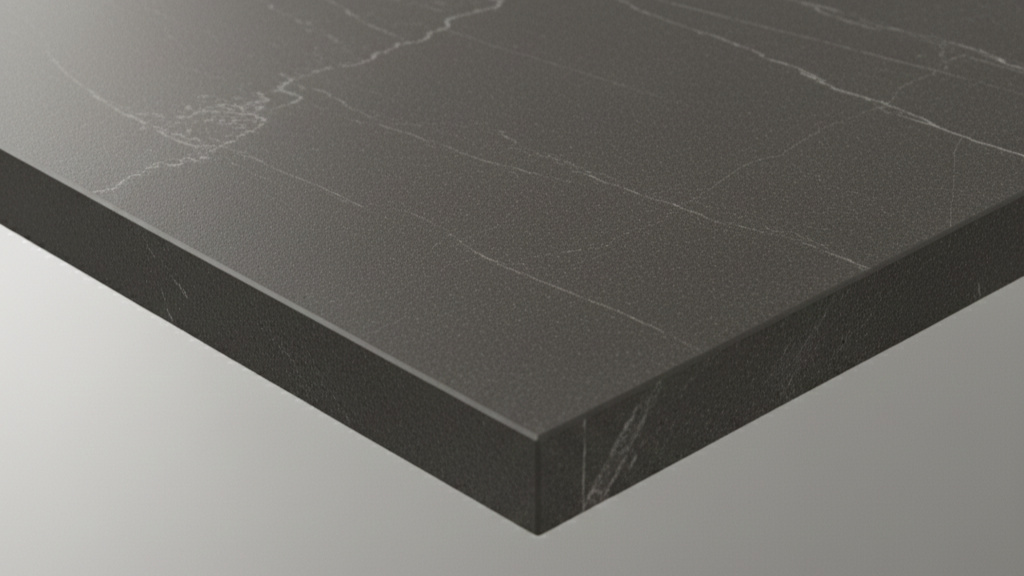

An ultra-compact countertop is an engineered surface created under extreme heat and pressure. The process bonds quartz, porcelain, and glass particles into a nearly indestructible material.

Manufacturers heat raw materials to 2,191°F under 25,000 tons of pressure. This method creates surfaces with zero porosity.

The result mimics natural stone countertops. It resists heat, scratches, and UV damage better than granite or marble countertops.

Leading brands include Dekton by Cosentino, Neolith, and Lapitec. These materials contain no resins or binders. They’re also 100% inorganic, with densities of 2.44-2.53 g/cm³.

Standout countertop features include:

- Extreme heat resistance up to 572°F without damage or discoloration

- Zero porosity at 0.1% water absorption for complete stain resistance

- UV stability that prevents fading in outdoor installations

The manufacturing mirrors natural stone formation. It compresses thousands of years into hours. You get a material tougher than granite, with a hardness rating of 7-8 Mohs.

What Is a Solid Surface Countertop?

A solid surface countertop is a manufactured material made from acrylic resin and mineral fillers. The formula bonds these components into nonporous surfaces without visible joints.

Manufacturers mix 67% aluminum trihydrate with 33% acrylic resin. The blend hardens in molds at room temperature.

The result offers design freedom that stone cannot match. Fabricators can heat the material to form custom curves and edges.

Leading brands include Corian, Hi-Macs, Staron, and Wilsonart. These materials use similar acrylic-based formulas. They weigh 1.7 g/cm³, which is lighter than stone alternatives.

Standout countertop features include:

- Renewable surfaces that sand away to remove scratches and burns

- Seamless fabrication that hides sink joints and visible seams

- Thermoformable properties that mold into curves and custom shapes

The homogeneous composition means colors and patterns run throughout the entire thickness. You can repair scratches, burns, and damage with sandpaper.

Ultra-Compact Countertop Materials

Ultra-compact surfaces fuse natural minerals into a single solid slab. They contain no resins or binders.

Main components:

- Quartz adds scratch resistance and strength

- Porcelain resists heat and weathering

- Glass adds color and pattern variety

- Silica increases density and durability

- Metallic oxides add natural color and UV stability

These combined materials create a surface tougher than natural stone. You get the look of granite with better heat, scratch, and stain resistance.

Solid Surface Countertop Materials

Solid surface countertops blend acrylic resin with mineral fillers. The result is a smooth surface with consistent color across the slab.

Main components:

- Acrylic resin binds the surface together

- Aluminum trihydrate adds strength and heat resistance

- Mineral fillers increase density and durability

- Pigments create a consistent color throughout the material

- Polyester resin offers cost-effective binding in some brands

The soft composition allows heating and shaping during installation. You can also sand out scratches and burns to restore the original finish.

Ultra-Compact vs Solid Surface Comparison

The two countertop surfaces handle heat, scratches, and repairs in very different ways. This table breaks down how both materials compare.

| Comparison Factor | Ultra-Compact Countertops | Solid Surface Countertops |

|---|---|---|

| Durability and Longevity | 50+ year lifespan with minimal wear | 10–20 year lifespan with moderate wear |

| Scratch Resistance | Mohs 7–8, resists knife marks | Lower hardness, shows surface scratches |

| Stain Resistance | 0.1% porosity, resists stains | Non-porous surface, resists most stains |

| Heat Resistance | Tolerates 572°F, withstands hot cookware | Damages at 150°F, requires hot pads |

| UV Resistance | Stable in sunlight, suited for outdoor use | Fades and yellows in sunlight |

| Maintenance Requirements | No sealing, easy cleaning, hard to repair | No sealing, easy cleaning, simple to repair |

| Cost | $55–115 per sq. ft. installed | $35–80 per sq. ft. installed |

| Aesthetic Options | Realistic stone or concrete visuals with subtle texture | Smooth surfaces with solid or patterned designs |

| Edge Options | Eased or square edges only | Bullnose, ogee, bevel, custom curves |

| Surface Finishes | Polished, matte, textured, silk | Matte, gloss, semi-gloss |

| Physical Properties | 8–30mm thick, large slabs, heavy weight | 6–19mm thick, smaller sheets, light weight |

| Best For | Outdoor kitchens, high-heat cooking, commercial use | Indoor baths, integrated sinks, budget projects |

Ultra-compact is better suited for strength and outdoor performance. Solid surface is better suited for easy repair and design flexibility. Your choice depends on whether you value extreme durability or creative customization.

Also Read: 5 Easy Ways to Update Your Kitchen (Without Renovating)

Ultra Compact Countertops Pros and Cons

Ultra-compact surfaces give you durability and a modern look, but need expert installation. Here are the advantages and tradeoffs.

Pros of Ultra Compact Countertops

- High durability: Resists chips, scratches, and impacts better than granite or quartz

- Heat resistance: Withstands hot cookware without scorch marks or surface damage

- Stain resistance: Needs no sealing, resists daily spills, and remains easy to maintain

- UV resistance: Keeps color under sunlight and outdoor exposure

- Large slab format: Covers broad areas with fewer seams and flexible design options

Cons of Ultra Compact Countertops

- Hard to fabricate: Needs specialized tools for cutting and shaping

- Limited supply: Few fabricators and installers carry the material

- Longer project timeline: Limited availability can extend wait times

- Limited repair options: Damage is hard to fix and may need replacement

Precision Countertops carries Dekton by Cosentino in various styles and finishes. Visit our showroom to see ultra-compact surfaces in person and get expert guidance on your project.

Solid Surface Countertops Pros and Cons

Solid surface countertops are easy to repair, but can get damaged by heat. Here are the strengths and limits.

Pros of Solid Surface Countertops

- Nonporous surface: Resists stains, moisture, and bacteria without sealing

- Seamless appearance: Forms tight joints with integrated sinks and backsplash

- Simple maintenance: Cleans with soap and water for easy upkeep

- Repairable surface: Sands out scratches and damage to restore the original finish

- Affordable pricing: Costs less than granite, quartz, or marble and comes in many colors

Cons of Solid Surface Countertops

- Poor heat resistance: Hot pans cause discoloration, melting, or cracks on contact

- Soft material: Sharp knives and tools scratch the surface during daily use

- Chemical sensitivity: Harsh cleaners damage or discolor the surface

- Visible wear over time: Scratches and scorch marks show more on glossy finishes

Precision Countertops carries Corian, Hi-Macs, and Wilsonart in dozens of colors. Visit our showroom to see solid surface options and discuss your kitchen or bathroom project.

Best Uses for Each Countertop Type

Ultra-compact and solid surface countertops solve different needs in your home. Choose the countertop that works best for how you use your space.

Ultra-Compact Surfaces Are Best For:

Ultra-compact countertops work best in spaces that face heavy use or extreme heat. These surfaces handle harsh conditions other countertop materials cannot.

- Kitchen countertops and islands: Resists hot pans, frequent food prep, and daily wear

- Outdoor kitchens and BBQ areas: Stands up to sunlight, rain, and temperature changes

- Bathroom vanities: Prevents damage from water, stains, and cosmetic spills

- Flooring and wall panels: Creates seamless surfaces and durable shower enclosures

- Statement countertops: Mimics natural marble veining for a dramatic visual look

Solid Surfaces Are Best For:

Solid surface countertops work best where you need seamless design and easy repairs. These surfaces shine in spaces that value clean lines and low germ risk.

- Kitchen countertops and islands: Form sections without visible seams for a smooth look

- Bathroom vanities: Create seamless countertops with integrated sink bowls

- Restaurant counters and bar tops: Resist stains in high-traffic food service spaces

- Shower walls and wet-area cladding: Reduce grout lines and fight mold buildup

- Laundry rooms and utility spaces: Block water damage with nonporous surfaces

Match the material strengths to your priorities. Heat and outdoor needs favor ultra compact. Design flexibility and repairability favor solid surfaces.

Compare Countertops in Person at Precision Countertops

Choose ultra-compact for heat resistance and outdoor durability. Choose solid surface for seamless design and easy repairs.

Visit our Wilsonville showroom to see full slabs of Dekton, Corian, Hi-Macs, and Wilsonart. Our designers help you pick materials, colors, and edge styles that fit your countertop project.

Schedule your showroom visit today

FAQ: Ultra-Compact vs Solid Surface Countertops

Get quick answers to common questions about ultra-compact and solid surface countertops.

How long do ultra-compact countertops last?

Ultra-compact countertops last 25-50+ years with proper installation. The dense material resists daily wear without breaking down. The surface maintains its look and performance for decades without sealing.

How long do solid surface countertops last?

Solid surface countertops last 10-20 years with regular care. Professional refinishing every 10-15 years removes scratches and heat marks. Proper maintenance can extend the lifespan to 50 years in some cases.

Can you use ultra-compact countertops outdoors?

Yes, ultra-compact countertops are UV-resistant and work outdoors. The material never fades under direct sunlight or cracks in freeze-thaw cycles. Rain, snow, and temperature swings from -40°F to 100°F+ cause no damage.

Can you paint solid surface countertops?

Painting solid surface countertops rarely lasts long-term. The nonporous surface rejects most paints without heavy sanding. Professional refinishing or replacement gives better results than paint.

How thick are ultra-compact countertops?

Ultra-compact countertops come in 8mm, 12mm, 20mm, and 30mm thickness options. Most kitchen countertops are 12mm or 20mm thick. Commercial spaces and large islands use 20mm or 30mm for added strength.

How thick are solid surface countertops?

Solid surface countertops come in 1/4 inch, 1/2 inch, and 3/4 inch thickness options. Most homes use 1/2 inch material for balanced cost and durability. Commercial spaces specify 3/4 inch for heavy-use areas.

Where to buy ultra-compact countertops?

Buy ultra-compact countertops from certified fabricators and authorized dealers. Precision Countertops offers expert guidance on both materials with professional installation in Oregon.